Global chip supply update: why shortages can return even after “recovery”

Recent improvements in the chip supply landscape have brought relief to multiple industries, especially automotive and electronics. However, experts warn that these shortages might resurface despite the apparent recovery. Understanding the factors behind these fluctuations is crucial for businesses and policymakers navigating the semiconductor market.

Current State of the Chip Supply

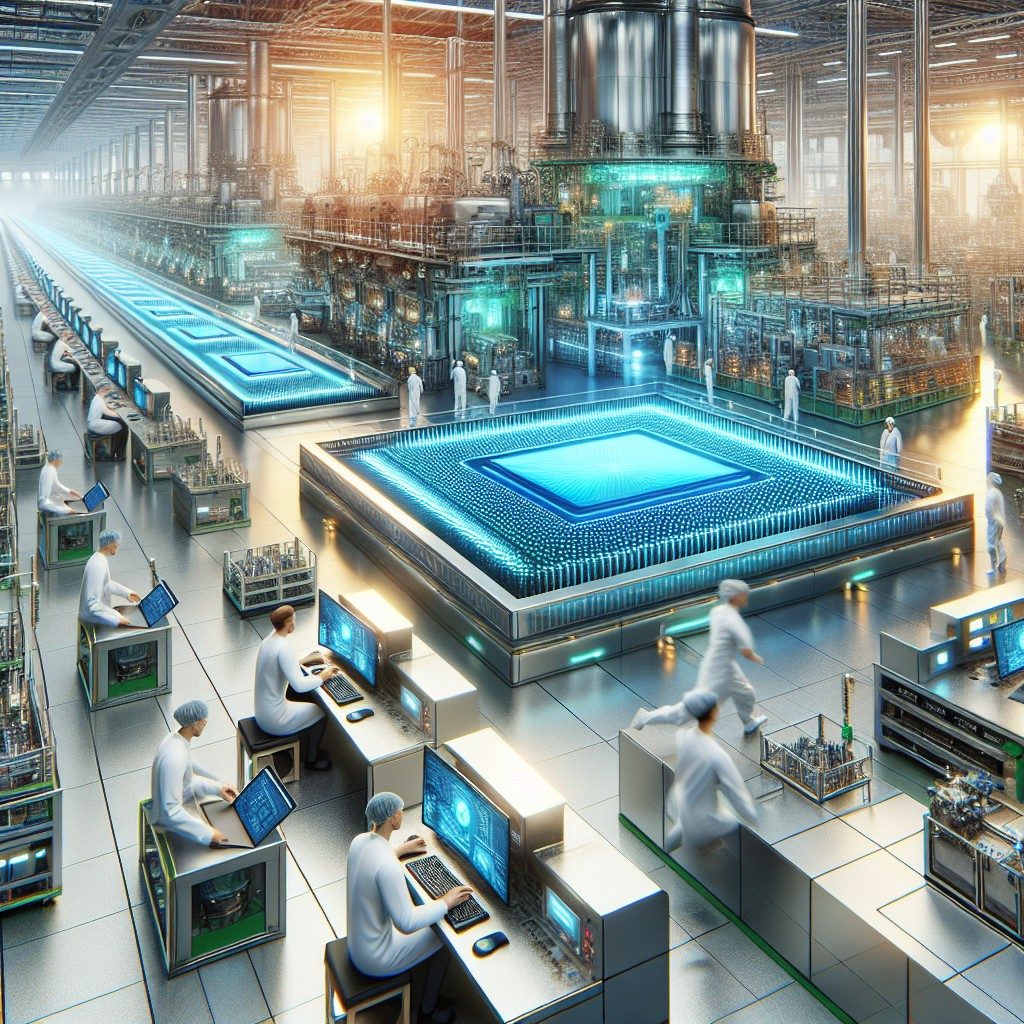

The chip supply has shown marked improvement in the first half of 2024 following a period of significant disruption caused by the COVID-19 pandemic and geopolitical tensions. Key semiconductor manufacturers have expanded capacity, and supply chains have gradually stabilized. Yet, the demand for chips remains volatile, influenced by global economic conditions and emerging technological needs. The interplay between supply capabilities and diverse market demands continues to make the chip supply situation complex.

Factors Leading to Potential Shortages Despite Recovery

Despite advancements, several structural issues threaten the balance of chip supply. Geopolitical tensions between major producing countries can prompt export restrictions, limiting access to essential materials or manufacturing technology. Additionally, the semiconductor industry relies on highly specialized manufacturing facilities with limited flexibility, making rapid scaling difficult. Natural disasters or unforeseen disruptions at key fabrication plants further jeopardize consistent chip supply. The increased complexity of modern chips also extends production lead times, which can contribute to future supply constraints.

Increasing Demand Challenges

The demand for semiconductors continues to grow rapidly, driven by sectors such as electric vehicles, 5G technology deployment, artificial intelligence, and consumer electronics. This surge in demand puts pressure on the chip supply chain to maintain production comfortably above consumption levels. Even with new fabs coming online, capacity expansions often lag behind the pace of technological adoption. As industries integrate more sophisticated chips, the necessity for highly specialized production increases, compounding supply challenges.

Supply Chain Vulnerabilities and Solutions

Supply chains for chip supply are highly globalized, involving numerous intermediate suppliers and logistics services. Disruptions due to transportation delays, raw material shortages, or component bottlenecks can ripple across the entire semiconductor manufacturing process. Companies are now exploring diversified sourcing strategies and regionalizing production to mitigate risks. Investments in supply chain visibility and advanced analytics aim to predict and address potential disruptions proactively, although achieving complete resilience remains difficult.

Industry and Government Responses

Governments worldwide have recognized the strategic importance of securing chip supply by fostering domestic production capabilities and funding research. Initiatives like subsidies for semiconductor fabs and partnerships with industry leaders are underway in regions such as the United States, Europe, and Asia. The industry itself is prioritizing innovation in manufacturing technologies that can improve yields and reduce dependency on vulnerable supply links. These combined efforts seek to create a more stable and robust chip supply environment in the medium to long term.

Conclusion

While the chip supply has improved from prior shortages, the risk of future disruptions remains tangible due to geopolitical factors, evolving demand, and supply chain complexities. Stakeholders need to maintain vigilance and adaptability as the semiconductor landscape evolves. Continued investment and strategic coordination between governments and industry players will be essential to sustain chip supply and prevent renewed shortages in the years ahead.

Frequently Asked Questions about chip supply

What causes fluctuations in global chip supply?

Fluctuations in global chip supply are primarily caused by changes in demand, production capacity limits, geopolitical tensions, and disruptions in the supply chain or manufacturing facilities.

Why can chip supply shortages return even after recovery?

Shortages can return due to the industry’s reliance on specialized manufacturing, evolving demand, geopolitical risks, and potential supply chain disruptions despite current improvements.

How do geopolitical tensions impact chip supply?

Geopolitical tensions can lead to export controls, reduced technology transfer, or sanctions that restrict access to critical components and manufacturing equipment, impacting the chip supply negatively.

What industries are most affected by changes in chip supply?

Industries such as automotive, telecommunications, consumer electronics, and emerging tech sectors like artificial intelligence are highly sensitive to variations in chip supply.

Are there measures to stabilize the chip supply long-term?

Yes, governments and companies are investing in domestic manufacturing, diversifying supply chains, and adopting advanced production technologies to enhance chip supply stability over the long term.